O2 sensor measurement chamber

Selbstbau eines O2 Sensoren Testers

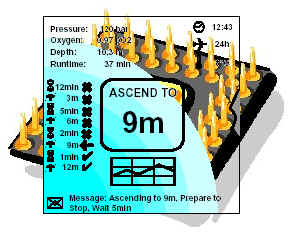

From the project OLED HUD came the idea to build one O2 sensors tester.

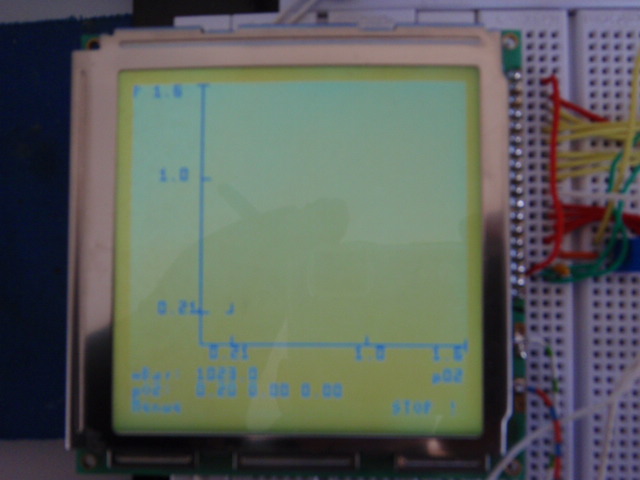

O2 sensors age with time (galvanic cell) and thus have no more linear characteristic. Especially in the range of pO2> 1.0 Curves then fall flat, or the sensor reaches 1.6 pO2 not even the final value.

To test this, sensors may therefore be a pressure-tight measuring chamber in and out with compressed air (max 9 bar of regulators) is applied. The pressure increase is a fixed flow allows small to (pressure increase over time).

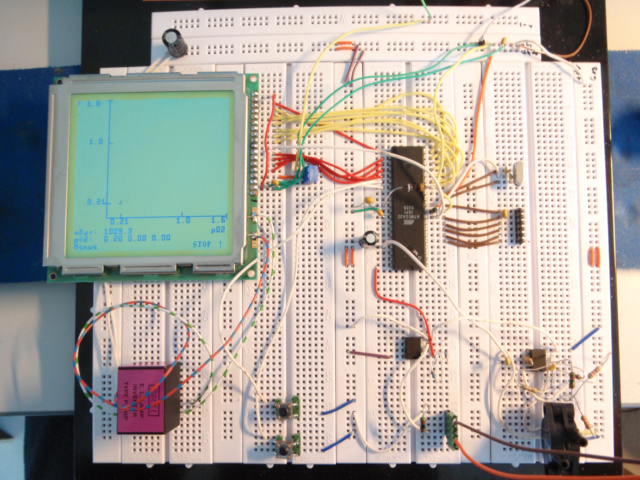

The sensors are measured while the electronics and values on the display graphically illustrated them. This allows linearity and full scale (1.6pO2) is determined to be very good.

What features are realized

- Indication of the measured chamber pressure

- Display of three sensors

- Representation of the measurement graphically in real time

- Display of measurement for each sensor (stored values, offline replay)

- Start and stop of measurement

- Termination of the measurement

The first consideration was now the chamber with oxygen filled. Good idea, but has a hook ![]() is because in the time in which the measuring chamber filled to 100% oxygen, there is no increase in pressure in the chamber (ambient) only when the chamber is closed (solenoid valve) causes a pressure increase, which can then be recorded and the pressure sensor. This results in pO2 = 1.0 to no curve on the display. (Y = const pressure, x = sensor value rises)

is because in the time in which the measuring chamber filled to 100% oxygen, there is no increase in pressure in the chamber (ambient) only when the chamber is closed (solenoid valve) causes a pressure increase, which can then be recorded and the pressure sensor. This results in pO2 = 1.0 to no curve on the display. (Y = const pressure, x = sensor value rises)

So now air was selected as the measuring medium. The pressure chamber is closed and the pressure continues to rise (Y-axis pressure is increasing with time). In a final value of about 9 bar, the sensors should then reach a pO2 of 9 x 12:21 = 1.89 pO2. This results in a series of measurements can, the pressure increase delayed by a needle valve (about 0.5 liters per minute).

Kategorie: Meßgeräte, Aktualisiert am 3. November 2016 von tauchcomputer | Log in